10th September 2007 – I left my bed at 4 o’clock. I started undoing most op the ropes. At 5 my father and me moved the hatches on two piles. At six we started the engine and tried to move the boat the other side of the canal. No problem, it is only 35 meters, but the wind decided to make It different. It took us 25 minutes to more the boat. The first time the boat nearly turned completely, what would not have been possible and cause us to be stuck in the canal (and blocking it). The second attempt took us more time, but in the end we made it.

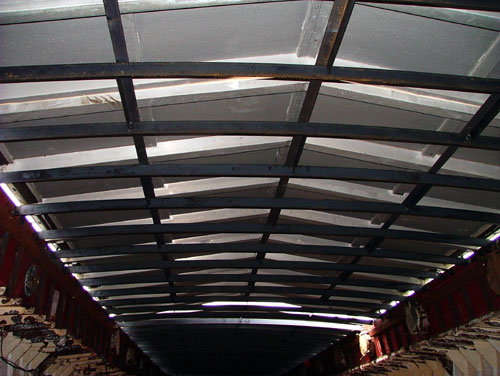

At seven, the plates were delivered and put into position.

Half an hour later we could move the boat back to its mooring. This took us less then 5 minutes since the wind was blowing us to the place.

The whole day we put the plates in the best position possible and touched them. We had to stop at some moment since it was raining to hard.

In the afternoon, all of the sudden the boat was very deep in the water. I didn’t notice, I only discovered the quay was higher then the boat. The man of the yard laughed and said the boat was sinking. To tired to get the joke I went looking for water in the bilges, but couldn’t find any. When I looked again I found the cause, water was very low, uncommon.

I called the nearest locks and asked if they were ware of the change of water level. Since one lock was broken, they had to lower the river so boats could move. You would expect them to warn you for the ropes, but they didn’t. I checked the mooring to see if the depth was still ok,, since it isn’t deep under the boat. My boat has a draft of 90cm, while I have 1.50 meters beneath the boat.

I still had to do a few ropes, but will wait till the water level is normal again.