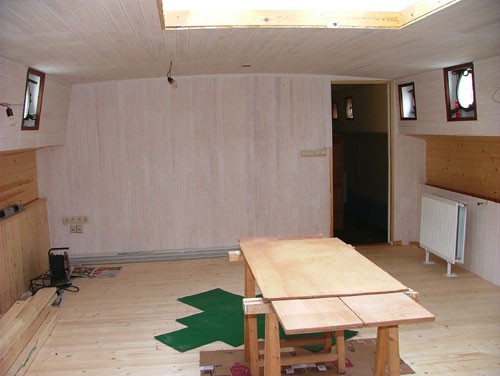

22nd September 2009 – In the evening all furniture came over from Ostend. It fitted in two cars and a jeep. It looks much smaller with the stuff in te hold. Another reason why I’m happy I painted the boat in light colours. All my furniture is dark wood.

Category: MS Watergeus - page 26

20th September 2009 – The heating element in the wheelhouse is about to be replaced. The wooden panel behind it was rotten and falling apart. With the remaining wood I made a new one. It still needs to be vanished, but it is looking good. Since it is a 22mm multiplex sheet the heating element can hang on the plate, making it easier to clean the floor.

On Tuesday I’ll bring my furniture over from my parents place to the boat. Since they have to go through the hatch on the roof all hatches around it need to go. The hold was cleaned and all stuff no longer needed was stored away.

19th September 2009 – A few more details in the living room had to be sorted out. Also two windows had to be framed in the bathroom.

The whole afternoon I painted the living room and corridor. The corridor is now finished.

At noon time one the paper boats was passing by. Yesterday every guest had to make a paper boat with a candle. Today one was still afloat.

13th September 2009 – In the morning I made the two remaining inspection holes and finished the floor in the corridor heading to the living room. In the late afternoon I started painting but give up very quickly. Three days of work is more then enough.

12th September 2009 – In the morning we started with the floor in the living room. A very hard job, but we made a lot of progress. By the end of the evening, we were half way.

11th September 2009 – In the morning I went visiting my neighbour at the yard. In the afternoon we boxed the pipes of the central heating.

8th September 2009 – While building the new central heating I had the tools to remove the old pipes. All of the sudden, I had plenty of more space in the engine room. By the end of the evening the hold was finished and the heating in the storage area. I can now start to finish the remaining woodwork in the hold.

7th September 2009 – Another major project is the central heating. The easiest part is the hold itself, everything is new and straight without metal bulkheads. The hardest part is the old back accommodation and the engine room.

6th September 2009 – In the morning we finished the floor in the kitchen and in the afternoon the entrance of the ship. Besides the box on starboard side where the heating is coming, all the big woodwork is done. Another step closer to living in the hold.

I used softwood (Pine from Norway) as floor for the living room. Many people recommended me not to do so. There are several reasons why I did it anyway. It is cheap, four centimeters thick and it will be oiled. I wanted a floor that was not tongue and groove so I could easily remove it to get to the hull on the yard. Screw are holding the planks to the multiplex underneath it. By the time the four centimeters of wood will be gone, so am I. I don’t mind it gets damaged on some points, since the floor in the office space, corridors and sleeping room is Azobe. This floor came from a cargo hold and is also damaged.

5th September 2009 – We finished the woodwork kitchen and living room. Small gaps were closed and a few details touched up. Everything is now ready for painting.

The heater was probably the biggest piece that had to enter through the door, so we could now finish the entrance hall as well, without having to risk to break everything out.

4th September 2009 – Today they delivered the floor for the kitchen and living room. Since every piece was over five meters in length it was a big job to get it aboard.

In the afternoon they called to tell me the heating system, pallets and heating elements would be delivered today instead of tomorrow. A bit surprised I had to make some more room in the living room. When the truck arrived I was even more surprised by the volume of pellets that had to enter the hold.

3rd September 2009 – The preparations of Monday were still good, but I added a few extra ropes to the anchor in case one would break. Since the anchor is not 150kg but 300kg I didn’t want to make any unnecessary risks.

When the crane came I was ready and in a short period the anchor was mounted. A good preparation was the key to this quick and successfully operation where many people doubt on it…

After the anchor was in position, we raised the little speed boat. This took us more time but went fluently as well. Thanks to the crane man for his experienced help!

1st September 2009 – Since a lot of new materials must be loaded in the hold, it was time to clean it out thoroughly.

31st August 2009 – My second anchor is on the front deck. Thursday, a friend is coming with a crane. I moved the chain through it’s gate and dropped it along the hull. I hope to put my anchor in position if the crane is long enough. I cut the anchor loose from the ship since it was welded a few years ago.

I built a small box for the heating element near the water tanks. Only a small wall was needed, but by the time I was finished it was also a work bench and storage space.

In the late evening, I cleaned another part of the deck. The idea of cleaning a square meter a day is not realizable.

30th August 2009 – Another inspection hole was built, two more to go and I can build my finishing floor. Since the remaining wood is stored where the holes need to be built, I can’t do it right now.