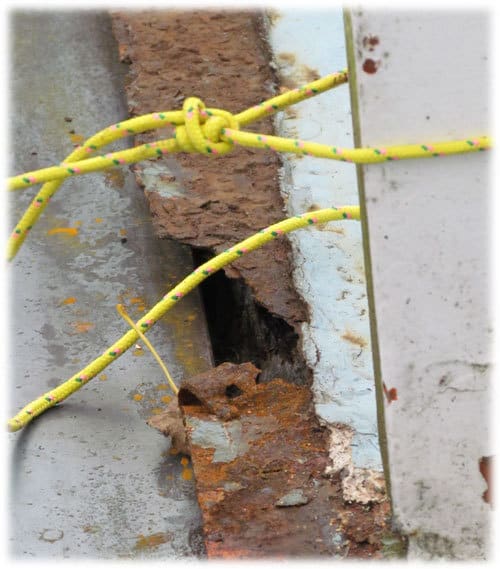

23rd November 2013 – There are so many little leaks in the boat. Most of them were nicely hidden by the previous owners. It took me a whole day to remove and close two portholes and two leaks in the old support of the towing mast – sleepmast -.

I decided to close the old outlet of the toilet. Most of the work was done yesterday. Today I welded a plate and bracket over the old pipe.