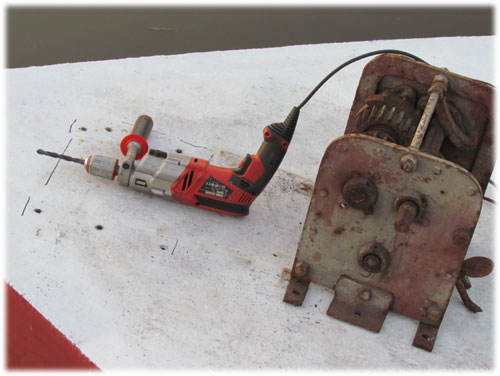

8th April 2012 – There are two more things that need to be done on the bow. One of them is a support for the cable sliding along the deck when the anchor is dropped. The other one is the railing on the bow. I wasn’t expecting to finish this job in a half a day, but we did.

The bow, which has been has been the subject of several discussions is finally looking like I really wanted it to look!

My parents came to help as well. They sanded the original ceiling in the living room and did some wood work.