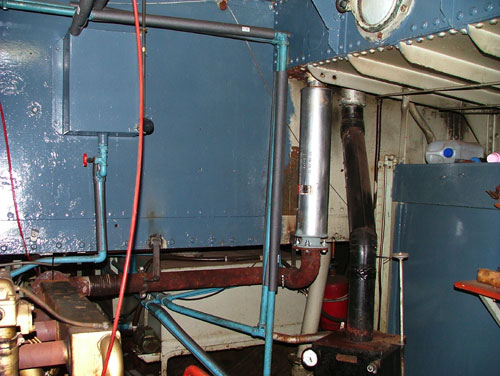

30th November 2007 – Quite unexpectedly they came today for replacing the exhaust. Last week they took the ring of the exhaust with them and now they had welded the new exhaust on this ring. This ring was bolted to the existing pipe and welded on the roof of the engine room. Two special made metal pieces were welded to hold the exhaust. In the early days the exhaust was only bolted to the roof, so it had to hold his own weight. This has changed now and will likely no longer cause it to break when it becomes rusty.

I’m happy with the result since it takes less space and the engine makes much less noise!

After the exhaust, it was time to replace the oil. The oil in the engine is at least five years old, so it was the perfect moment to change this and the oil filters. For the oil to change it needs to be thin. The oil was very thick, so the only solution was running the engine. I’m always proud with my engine, since it starts straight away, turning the key and it runs. Well my engine had not run for three months and it didn’t start. Batteries were flat. I always charged them so I had no idea. After checking everything I learned a new thing, filling batteries with water. Seems logic, but I didn’t know I had to refill my batteries with water. We added 15 liters of water in the two batteries. A few minutes later, the engine started. It ran for half an hour, then we switched it of, changed the oil and it ran again. So twice running the engine in an hour on the same batteries. A little bit of water can make a difference.

It is pretty simple to replace oil filters, but you just need to know it…