6th April 2012 – The ship had a railing on only one side. We never had the time to finish this project in Sluiskil. It certainly is not the most important job, but it looks nicer. When I’m going to the yard in May, I don’t want to carry all these length of pipe with me. They are now stored on the hatches of the Watergeus.

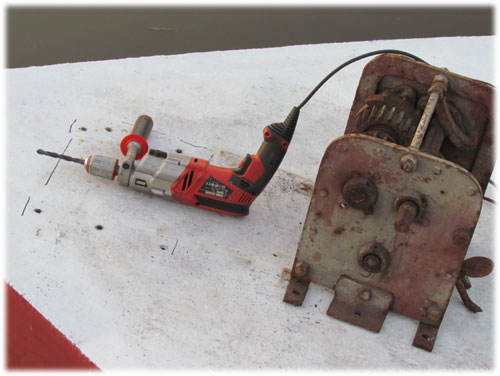

Today I cut the feet for the railing and welded them on the boeisel of the ship. A very time consuming job! Welding RVS pipe on metal is not that easy.