21st May 2009 –

21st May 2009 –

20th May 2009 – In the evening I continued with the floor and insulating it as well. Since the watertanks are underneath it, I did find it important to put some insulation.

19th May 2009 – I started building a frame for the floor in the front cabin. Having build several frames in the past for different areas on the boat, I must say this one seems a little harder to built. Everything is bended and the metal construction exists of old sheets of metal they must have reused in the sixties when building this cabin.

18th May 2009 – Coming weekend I want to build the frame for the front cabin. Since not all my tools were removed, I decided to clean it. Besides some wood, there were also steel plates, a heating element, some pieces for the bow rudder, a few hoses, a box with spanners and a lot of paint.

It did obviously took more time then planned to remove that much stuff out of this small area.

17th May 2009 – The hardest part after an event is to clean everything up and bring back the tools for working. I must say it all went a bit slower then hiding them.

16th May 2009 – I continued cleaning the hold and repairing the little party. It had been raining all day. We built a a party tent at the entrance and decorated the ship with many flags.

15th May 2009 – Tomorrow I have a barbecue with some colleagues. They always wanted to see how I live on a barge, so it was the perfect moment to combine this with a barbecue. The preparation took most of the day since the hold had to be emptied. This was one of the reasons why I had built the storage system last Wednesday. The more stuff I could permanently store in the front or back, the better.

The boiler was connected to the water system and some fittings were mounted on the water pipes as well.

13th May 2009 – The plumbing for the bathroom is ending it’s final stage. A few more pipes were connected, but it could all have been done more easier if the frames were straight and less corners were built.

10th May 2009 – In the early morning we removed the pieces from the bow rudder that I took from another spits barge a few months ago.

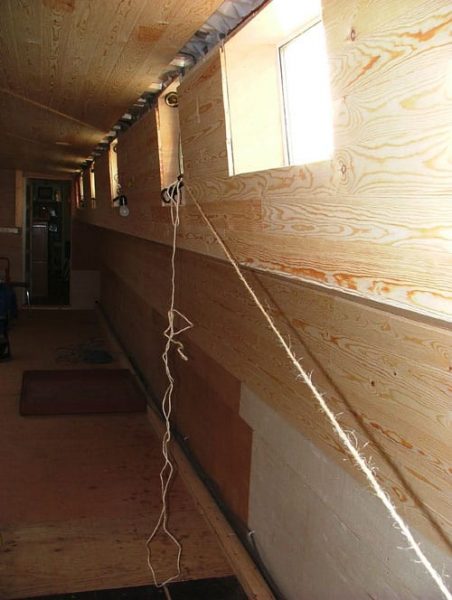

9th May 2009 – During the day we did the other side of the living room in pine. A few little gaps on the side were filled as well. I think with another two days the whole living room will be ready for painting.

5th May 2009 – In the afternoon I filled the tanks up to their maximum level (1000 liters each) and emptied them through the pump that was connected last week. I had a nice deck wash!

The outside dining table was painted. It was now the third year I had it, so it had to be painted once to extend it’s lifetime.

In the forepeak, the floor was painted red. If it turns out to be nice, I might do it as well in the living room. It’s an idea from another ship.

4th May 2009 – In the late evening, I finished the floor in the forepeak. Since not all planks were fixed and I felt through recently, I decided to finish this job first. Before you know, somebody else could fall through as well.

3th May 2009 – In the morning we reconnected the tanks. We let them dry before putting water in and yes they remained dry, no leaks! In the afternoon we made the copper fittings for the bathroom and kitchen.

2nd May 2009 – While cleaning out the bathroom for the the plumbing works tomorrow, I had the bright idea to already build the ceiling. I had some wood left from the sleeping room and should be enough for the ceiling, so it was.

In the evening I put a porthole in the bulkhead between the fore peak and the front accommodation. This was an attempt to have more light in the forepeak without making holes in the deck or hull. I have now some more light but it really isn’t that spectacular.

1st May 2009 – The yacht season has started, this means a lot of yachts were passing by today. At least thirty yachts, mall and big passed by. Some of them running the engine at a ridiculous speed, knowing a few hundred meters further there is a bridge and they have to stop anyway.

We continued on the living room, finishing one side by the end of the day.