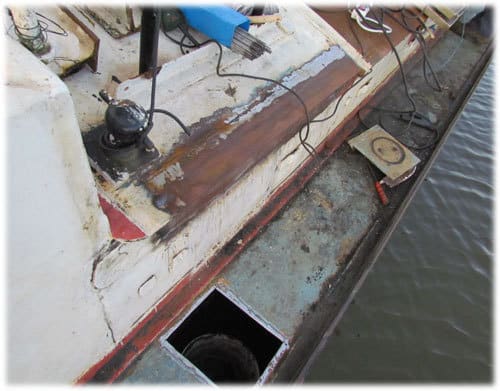

29th December 2013 – The engine room doesn’t smell well with the oil and water in the bilges. I mounted the air vents that came with the ship. I hope with some fresh air, it will make it easier working in the engine room the next couple of weeks.

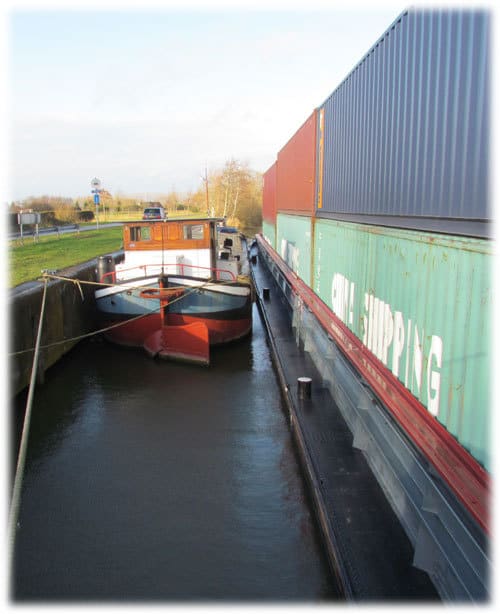

The mast at the back of my ship broke when I turned around in Merelbeke. A friend salvaged the mast and she is now back on the boat!