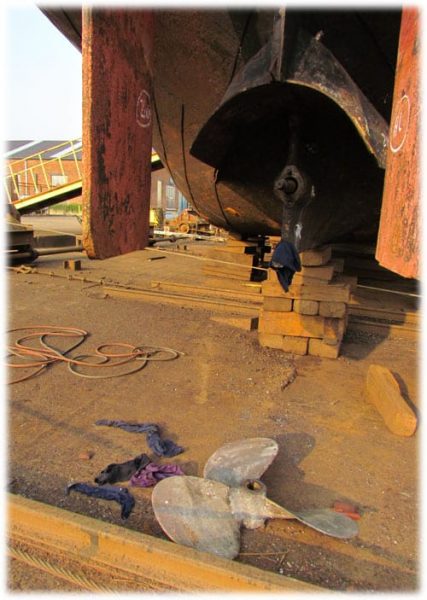

30th May 2012 – When I woke up, people of the yard were measuring the propeller and the amount of space between the bus and the shaft. It was to much so they will have to put a new bus on the shaft.

At eleven o’clock I had a visit of the surveyor. It took us a few hours to go around the ship and check the thickness of the plates. Cleaning the metal with a slap tool is a very hard job. I didn’t like it!

In the afternoon I heard the verdict. The ship was sound, but I had to double one plate and one rivet needs welding. So besides the propeller there are no other major costs. They will weld some anodes to the ship to prevent the boat from rusting quicker.

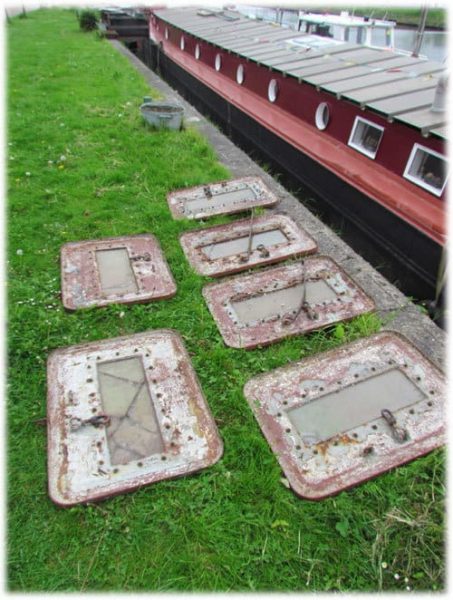

The yard wants to weld the plate tomorrow. I have two options, cutting open the floor or filling up the ship with water in the bilges. I choose to cut open the floor and do fire guarding myself.

My parents started painting the hull in the evening, when the temperature got just below 25°C.