27th October 2013 – I have been working nearly continuously in Beernem on the boat. Today, I went to take some pictures at the yacht harbour in Bruges.

27th October 2013 – I have been working nearly continuously in Beernem on the boat. Today, I went to take some pictures at the yacht harbour in Bruges.

26th October 2013 – After making an entrance through the back accommodation, I noticed some of the cabin metal was bent. By welding some supports, I made it stronger again. Where possible I straightened the metal as well. In the afternoon I painted the new supports and some of the older metal.

The wheelhouse got another coat of special paint for the roof. This paint is silicon based. Therefore water can’t enter the wood. The wheelhouse itself got her second coat of oil, looking shiny again!

23rd October 2013 – We cut up the remaining wooden hatches and put them in my car. In the afternoon, an entrance was made to walk from the back accommodation into the hold. This little change makes a big difference. You can now walk and run through the boat from one side to the other without having to go outside.

22nd October 2013 – While I was welding, my mother sanded down the wheelhouse. It is still a nice weather, so we must take the most out of it.

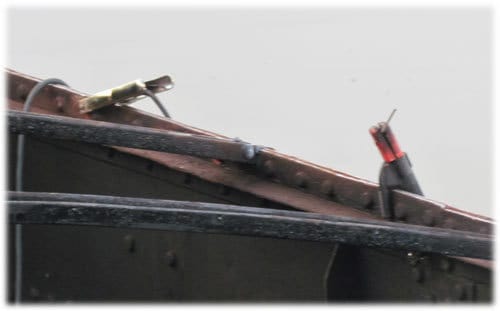

21st October 2013 – I finalized welding the roof. The boat should be dry now if it rains. It gives me a good feeling to know you are safe for the winter. A metal roof is one of the milestones in the conversion of the Aquarel. Later that evening I continued closing holes in the roof of the back accommodation, a job I will continue with tomorrow when it is daylight again.

20th October 2013 – There are still some holes in the roof of the back accommodation. Around a mast support, the previous owners used filler.

I removed the support, filler and chipped away most of the rust. I put a new plate on top and welded the roof. it wasn’t easy, since every few centimeters, I burned another hole.

10th October 2013 – I’m happy the sheets were on earlier this week. I haven’t see that many rain for years coming out in one day! I didn’t have a look yet inside, but some water will have come in. I still need to weld the metal plates.

Welding near wood can cause fire. Welding and fire are well known to me after last year’s incident aboard the Hornblower. I removed the sleeping accommodation at the back of my ship. It was rotten and to close to the bulkhead where I have to weld.

8th October 2013 – After a week of hard work, it was time to put the metal sheets in position on the roof. This was an easy job. We moved the boat several times and lowered the sheets with my neighbour’s crane.

Once everything was done, we had a drink and moved the ships by hand. I’m now near to land and my neighbour alongside. Since none of the engines worked it took some time and a lot of effort to swap the vessels.

7th October 2013 – Owning a boat and maintaining it as a hobby is suffering when there are deadlines!

The last bits have to be done today. Welding another four small pieces and some gaps. That was the plan for this evening. The last effort and energy I had left was spent today. I managed to keep my deadline. If I would ever do it again on such a short time period: NO!

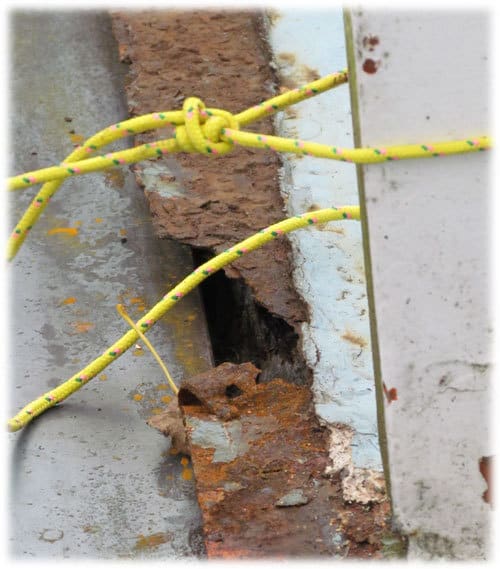

4th October 2013 – Knowing I can’t save the hatches, I decided to remove the roofing felt and hatches with a crane. This means, ripping everything apart. I put a rope through the skylights and pulled the hatches of with a crane. The only risk was that the roof could fall into the ship or my neighbours boat. Once everything was on land, I could start with the cleanup and the welding. It will probably take three days to make the ribs and supports. No time to lose!

1st October 2013 – I have to remove 44m2 roofing felt from my wooden hatches. I want to save them for later. The roofing felt was burnt on the hatches and on the den. This makes it totally water proof and solid. It also makes it a nightmare for me . With an axe, I tried to separate the den from the hatches…