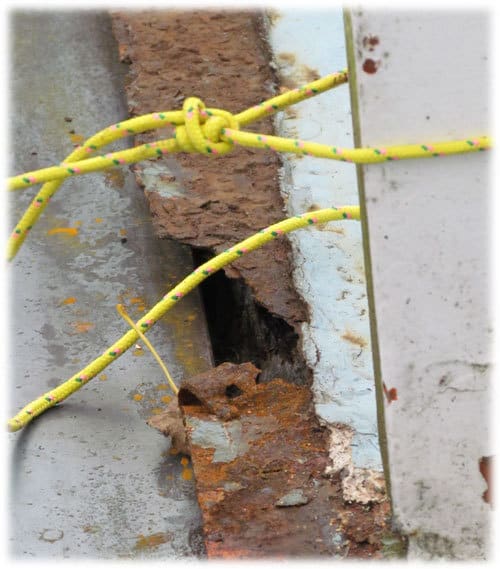

26th February 2007 – In the late morning / early noon I started making the last preparations for the sailing. Realizing a lot of the the bulkhead needed to be welded, I started doing it myself.

Between some welding sessions, I helped moving a boat by hand and celebrated somebody’s birthday.

In the evening, the welder came to finish what I had started.

Taking goodbye of the people I’ve lived with, we decided to sit inside my neighbour’s ship and drank a beer. Half an hour later we heard somebody shouting their was a fire and when going upstairs, smoke was getting out of the pusher next to us. Together with him we extinguished the fire. There was a lot of damage. After an hour everything was under control and the fire had gone out. Cause, a diesel heater. So I ended my last day in Sluiskil in a very sad way.

By the time it was two o’clock, I went to bed, realizing a few hours later we would set sail with the Watergeus to Bruges…