31st October 2020 – The last day in Belgium before the lockdown. Thankfully the DIY shops will remain open. In the early morning I went to a cheap tools shop that is closing tomorrow. I was there at 8:30 and the shop opens at 9:00. There was already a massive queue of people waiting. I bought some paint for the Stern, screws and tools.. I lowered it by 11 centimeters. It still looks high, but the difference in colour makes it look strange. Once painted, I hope it will be better.

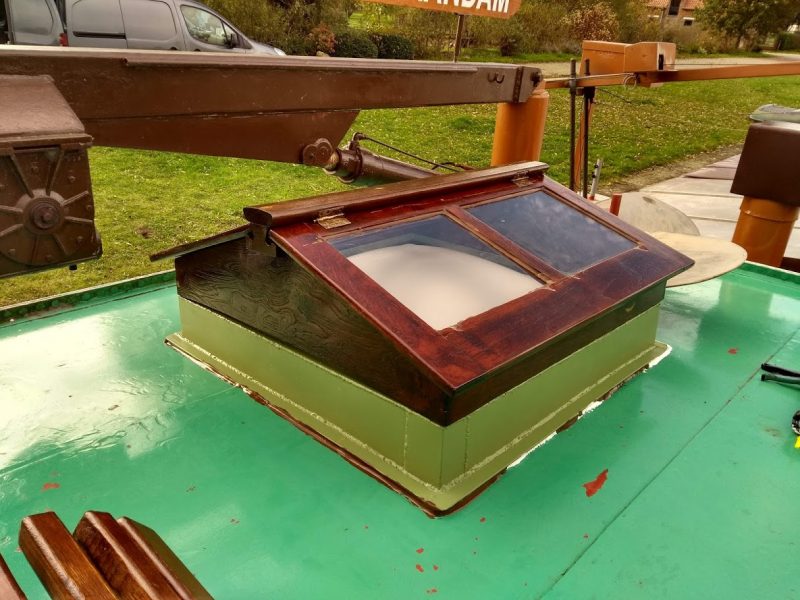

Then I started looking at the wheelhouse. It needs a lot of maintenance as well. I was surprised to see how quickly Tordino is deteriorating. Next weekend, I will continue to work aboard.