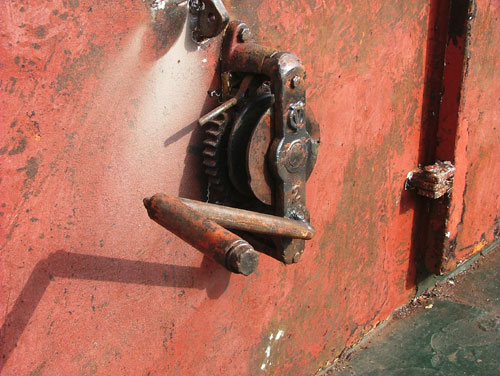

9th September 2007 – Last year I made the base for a working table in the evening school. Most of the metal pieces are now used around the boat, like the metal supports are at the anchor winch preventing the anchors to fall in the water. Anyway, with the remaining pieces and a bit of wood I finally finished the table. I’m planning on using it next week to clean the storm hatches of my portholes.

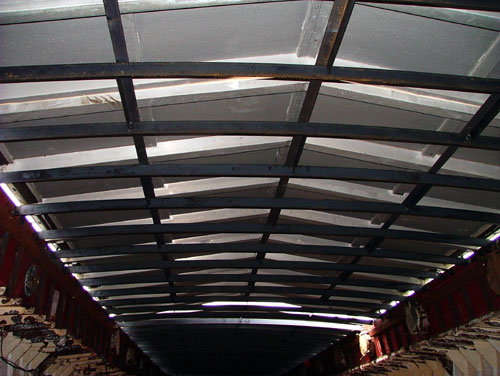

Tomorrow is the big day; the plates will be on the roof. So I removed a few ropes, made the electricity cable loose and cleared the gangways so everything should run smoothly. I don’t expect many problems tomorrow if it concerns moving the boat and the rope work.

An ex colleague came with her two children. They asked a lot of questions and the made sense. So I’m considering making a small part of the site with explanations for children. It is already fascinating for me to on a boat, so I can imagine how it must be for the kids!