7th June 2012 – We left at six o’clock and arrived three hours later on the mooring. Everything went well till I touched a 380v cable and hurt myself…

The rest of they day I decided to keep it easy and relax…

7th June 2012 – We left at six o’clock and arrived three hours later on the mooring. Everything went well till I touched a 380v cable and hurt myself…

The rest of they day I decided to keep it easy and relax…

6th June 2012: I have no experience on mooring a ship on a tidal river. They gave me some advice at the yard, but every few hours I woke up to adjust my ropes. One of the guys was afraid the front bollard wouldn’t hold the current, so I added a few more ropes.

The crew arrived at eleven o’clock and we started at one. We had to wait for the right tide. It was a nice and relaxing journey. The weather was not to bad. No rain and no wind. Sadly enough no sun as well…

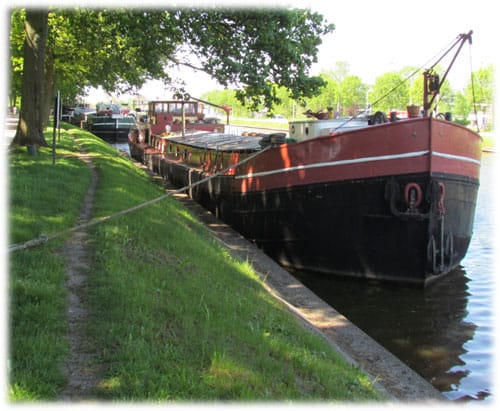

Late in the evening, we made it to to Beernem where I would stay for one night.

5th June 2012 – The shaft was fixed in the morning. We were lowered in the water at four o’clock. They had to wait for the tide before launching a ship in the water. Another ship was next to me. They had to lower it in the water before I could go.

While I had to wait, the crane people lifted my anchor so she is out of the water. The big skylight from the Frantsis is now underneath my hatches. It is looking better like this.

2nd June 2012 – While I have to wait for the bus of the shaft to arrive, we had plenty of time left. The weather was good, so we started painting. First the red part and then a silver line around the ship. I’ve painted the bow in silver as well. The rudders are now red again.

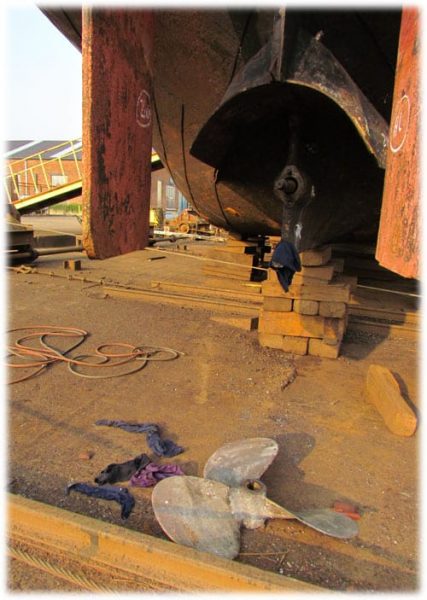

30th May 2012 – When I woke up, people of the yard were measuring the propeller and the amount of space between the bus and the shaft. It was to much so they will have to put a new bus on the shaft.

At eleven o’clock I had a visit of the surveyor. It took us a few hours to go around the ship and check the thickness of the plates. Cleaning the metal with a slap tool is a very hard job. I didn’t like it!

In the afternoon I heard the verdict. The ship was sound, but I had to double one plate and one rivet needs welding. So besides the propeller there are no other major costs. They will weld some anodes to the ship to prevent the boat from rusting quicker.

The yard wants to weld the plate tomorrow. I have two options, cutting open the floor or filling up the ship with water in the bilges. I choose to cut open the floor and do fire guarding myself.

My parents started painting the hull in the evening, when the temperature got just below 25°C.

29th May 2012 – At ten o’clock they started pulling up the first ship. One hour later, two tugs came to pull up the Watergeus. In no time, I was dry docked and they started cleaning the ship. At first sight, she looks in a reasonable good condition.

28th May 2012 – We left at six in the morning at Beernem. Three hours later, we arrived at the lock of Merelbeke. Another five hours later the Watergeus got on her destination, the yard in Rupelmonde.

Today is a holiday, so we moored alongside another vessel.

26th May 2012 – Driving your barges through Bruges is very annoying since it takes a lot of time with all those bridges. We left at 8.30 to be sure that, if something would go wrong, we have enough time to find a solution. And yes, it went wrong again. Now Steenbrugge would not open. If they would only maintain their bridges a little more…

Sadly enough, something went wrong. Yesterday the lock, today a bridge. After several attempts it opened in the end. They want us to have a survey for the ship, but their own equipment is useless…

I moored along two friend, had a nice evening, a BBQ and we talked for hours! At least, I had the feeling of being on a holiday!

25th May 2012 – We left at 8 o’clock in the morning. The first part, approximately 1km had to be done backwards. The ship has no reverse since the propeller is partly above the water. The wind was blowing us to the wrong side. It took a lot of effort, time and man power to get her trough the first bridge.

Once turned in the big dock, we heard on the radio that the lock was broken. A hydraulic pipe burst and the oil was in the lock. We moored along a tanker for a while and then decided to put the ship in a corner near the lock. This is a lovely place to put a ship, totally surrounded by green.

In the afternoon when the lock was working, and my skipper went home, they asked me to move my ship. I called another skipper who helped me moving the boat. Once in the lock, the doors wouldn’t close.

After two hours we were able to leave the lock and get a mooring near the mills. I didn’t make the planning, I’m starting to worry. The first day is gone and I live only moved the boat 3 kilometers.

27th April 2012 – With the little nice weather in the coming days, I finished welding the generator box on the front of the Watergeus. Now it still needs a cover and some decent paint. I’m not sure yet how to mount the exhaust.

In the afternoon, with some neighbours, we had a a beer and a laugh. A boat community is a very close group of people with the same sorrows and moments of happiness!

23rd March 2012 – The remaining deck underneath the hatches has been cleaned and painted. I also painted the box of the generator to prevent it from rusting. I only had a thin of yellow paint left from the Ross Leopard, so I used it.

19th March 2012 – I cut up another sheet of metal, now for the front. It took me some more time then usual since the plate was thicker and my spare grinder started smoking and shaking.

18th March 2012 – I made a simple design for the hatch / cover of the box. Two T-profiles were welded to the side of the box. On those profiles, a sheet will be sided. This sheet is also the cover. It is not waterproof yet, but it will at least stop most of the rain from getting to the generator.

While cutting the metal for the hatch, my grinder gave up on me. It is now the second tool that breaks down in less then a week. I guess they are become old…

17th March 2012 – The area between the metal roof and the hatches had never been painted before. I used it as a storage space for metal, tools and ropes. Today, we cleaned half of the area. Most of the metal has been lowered in the engine room. It does not only helps for the weight (propeller needs to be under water), all my metal is now in one place.

Once the area was cleared, I cleaned it with a metal brush and put some Zinga paint on the bare metal. I hope it will last several years!

11th March 2012 – I continued welding on the front hatch. I drilled a few holes to bolt the generator to the deck. This was not a real success. I have to reconsider how to mount the generator.