27th February 2007 – Today the Watergeus was moved to her mooring in Bruges. To read the whole story, click here.

27th February 2007 – Today the Watergeus was moved to her mooring in Bruges. To read the whole story, click here.

26th February 2007 – In the late morning / early noon I started making the last preparations for the sailing. Realizing a lot of the the bulkhead needed to be welded, I started doing it myself.

Between some welding sessions, I helped moving a boat by hand and celebrated somebody’s birthday.

In the evening, the welder came to finish what I had started.

Taking goodbye of the people I’ve lived with, we decided to sit inside my neighbour’s ship and drank a beer. Half an hour later we heard somebody shouting their was a fire and when going upstairs, smoke was getting out of the pusher next to us. Together with him we extinguished the fire. There was a lot of damage. After an hour everything was under control and the fire had gone out. Cause, a diesel heater. So I ended my last day in Sluiskil in a very sad way.

By the time it was two o’clock, I went to bed, realizing a few hours later we would set sail with the Watergeus to Bruges…

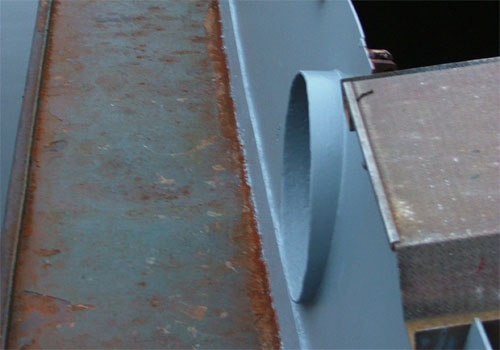

25th February 2007 – Today the last porthole was placed on the outside of the Watergeus.

24th February 2007 – When windows are placed, between their frame and the steel of the den, there is always a small gap, just enough to let water slowly enter the boat. Therefore you can make use of packing or silicon. It took us some time to fit the windows nicely and close them with silicon.

In the afternoon, the pipes for the toilet, shower and exhaust were placed on the waste water tank.

A lock was created to close the door from the outside and the inside. Later that evening some more welding was done on the bulkhead.

23th February 2007 – I had prepared everything for the trip (see article), but forgot about putting weight in the back, so the propeller would be under the water, not halve above. If the propeller is above water, you can’t sail backwards! Therefore I filled the new waste water tank with canal water.

The deck was painted on the side visible in Bruges. This will make her look nicer for when we arrive somewhere next week.

The holes for the portholes of the bedrooms and corridor were drilled, those of the kitchen and bathroom re drilled.

Some more plating of the watertight compartment were welded.

In the late evening the preparations for the trip were discussed, while drinking some coffee and beer.

22th February 2007 – In the morning, since the weather was dry, I painted the main entrance in black, according to the rest of the boat’s style.

While the first coat of paint was drying, the windows for the kitchen and bathroom were placed. Since I couldn’t drill with my hand, which is till not healing, the holes could not be re drilled to match the windows.

In the afternoon, I made a trip with Rinus’ new boat, the 1929 build Arma. She is a maatkast built on the dimensions for sailing through Friesland. It was a small but relaxing trip.

While sailing on the Arma, the welder started working on my bulkhead, the last thing that needed welding before leaving Sluiskil.

19th February 2007 – Today, my electrician placed the fusebox and the 380v 3-phase connectors on my boat.

In the afternoon, my dirty water tank was put into position. it took us one hour and six people to get the 1 ton heavy tank in a small space in the back of the ship.

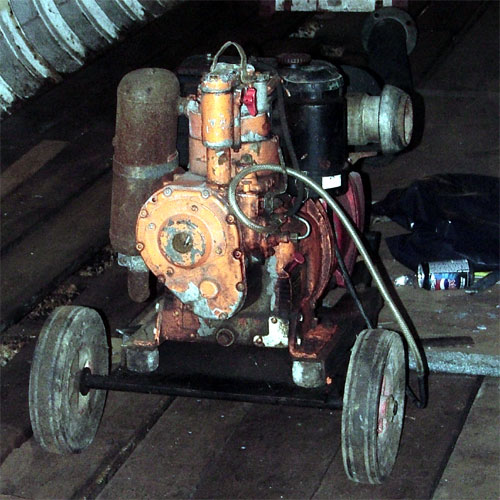

18th February 2007 – My ballast tank and my pump were delivered to my barge.

I swapped my old 1 cyl. Lister for a 1 cyl. Hätz with waterpump. Since I have a crane on my boat, I decided to put my crane into action and put the engine on my neighbours boat.

17th February 2007 – When arriving on my boat, the tank was nearly ready.

We drilled most of the holes for the screws of the windows. Over a two hundred holes were drilled! In the meantime the last places were welded on the tank and an inspection hatch was created.

7th February 2007 – It heavily snowed again, not only in Belgium but also in the Netherlands. Rinus, a friend of mine took some pictures of my boat in the snow.

27th January 2007 – Painting in a t-shirt with wed feet (boat was leaking) is not recommended in January! I was ill, something I’m certainly going to have trouble with in the next couple of days! Besides a bit of painting and disconnecting my neighbours Lister engine, not much was done today!

26th January 2007 – When arriving, all holes were made in the den for the windows. They only needed to be a bit more enlarged to fit the windows in, but the clarity I’ll get with those windows will be much more then with those eleven portholes!

The outside of the back accommodation and wheelhouse were repainted today, so she is starting too look nicer. I tried to paint the hull with tar, but because of the bad weather, my little boat wasn’t stable and when it started raining, I had to quit completely.

In the late afternoon, my engine ran for an hour. I had new diesel, so I tried the engine out on full speed in reverse and forward. She is still going strong!

25th January 2007 – This website moved to its new location: http://www.livingafloat.com. ‘Living Afloat’ will also become more then just a site on my boat. You’ll discover more in the future!

21st January 2007 – Today, an extra diesel tank was placed aboard my boat. I sold my spare Lister engine and the anchor from the back was moved forward.

The spare tank will be used for the heater in the living room (has to be build). It is now still the moment to put everything aboard the boat. Once in Bruges, there is no crane barge in the area.

20th January 2007 – Last week, I ordered some rubber to put on the den to protect the hatches. I will put it on just before leaving Bruges when all welding works are finished.

Besides cleaning the bilges, the technical room was repainted in a lighter colour. Last year I painted it black, not knowing what intentions I had with that room. The welder continued putting on the other windows.

In the afternoon, we drawed the lines for the six windows, mentioned in December 2006. those six windows are slightly curved and much more difficult to place. It is hard to miss with a porthole, but those windows, if one is wrong, you’ll notice straight away.

This job took us over three hours. Trying from the inside and from the outside. In the end, we worked from the eye and didn’t measure anymore. If it looks right for the eye then it was good. There is nothing straight on a boat, so what to use as a fixed point…