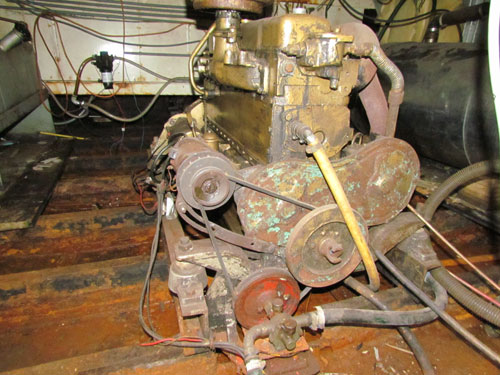

25th July 2011 – I have the boat now for three and halve months. I spent a lot of money, it took me a lot of spare time to get so far. When the windows in the back are replaced, the boat can be called dry. I don’t see anymore leaks from rain water. The bottom is fine, she was doubled by a previous owner. In September I want to replace the wheelhouse windows and start working on the engine.

If everything goes as planned, I hope to make my first trip next year. She won’t be finished, but at least I should be able to make a journey with the Hornblower.

Having worked on several boats in the last year, I can think this one being the biggest success for me. Some advice for starters: Make sure you have place to sleep aboard while working. When you are tired, you can go to bed without driving several miles! When there are nice people around you, it goes much quicker as well. You don’t loose motivation.