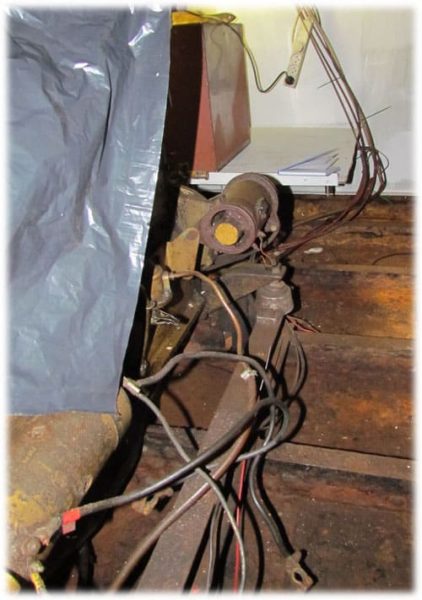

18th January 2012 – One of the first items in the engine room that need to be done is mounting a cable to switch of the engine. Now I need to grab a small piece of metal and lift it. While you lift it, the diesel pump no longer gets any fuel and the engine stops. It works fine, but this little leaver is next to the exhaust. It caused me already a few burning wounds on my arm.

To guide the cable I need some wheels and their supports. I also need a steel cable, preferably rvs. The gearbox need changing oil again, the cables from the starter motor towards the batteries need replacing. The water pipe from the engine to the outside is rotten. All these small things cost me over hundred EURO, without mounting them. So I was right, their is no such thing as a cheap boat (Blog, 16th January 2012).

Before I can mount the wheels, I need to weld some more ribs. I believe when the engine room is finished, she will be one of the most solid boats I’ve ever owned so far!