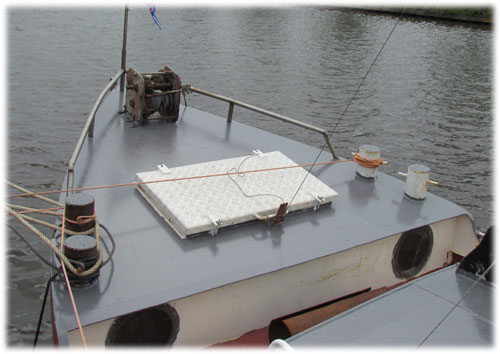

12th May 2012 – The bedroom is divided from the wheelhouse. Since I want the ship to has it strengths again for when another ship would more alongside, I’m extending a part of the bulkhead to the ceiling of the bedroom. A second reason for this metal part of the boat is that it can now carry some floating cabinets for my clothes and other stuff.

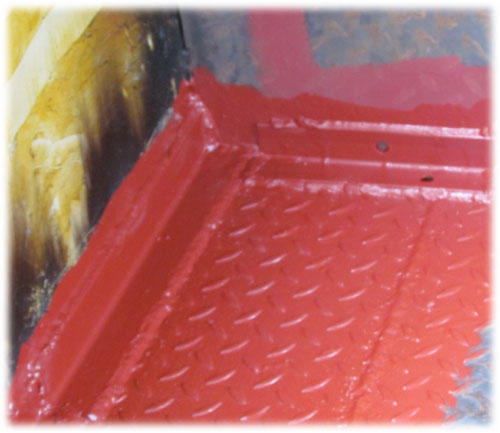

While welding the plate, some sparks must have touched dust in the engine room. The bilges were on fire in no time. Gray and black smoke started appearing out of the boat. I had nothing else but some buckets of water to kill the fire. It is certainly not recommended pouring water on oil, but it helped. The damage is reasonable seen to the flames that appeared.

A few pipes of the engine melted and everything is in black smoke. It will take some time to clean the engine room. It could have been much worse!

In the afternoon I gave up welding and cutting. I did some wood work for a while till I had enough of it for the day!